Plug Fans vs Centrifugal Fans for Data Center AHUs

01/29/2026In the engineered ecosystem of a modern data center, where uptime, efficiency, and scalability are paramount, the cooling infrastructure forms a critical backbone. At the heart of this infrastructure are Air Handling Units (AHUs), responsible for the precise delivery of conditioned air to manage the intense thermal loads generated by IT equipment. The choice of fan technology within these AHUs is far from a minor specification; it is a fundamental design decision that profoundly impacts energy consumption, system reliability, operational flexibility, and total cost of ownership. The debate primarily centers on two dominant technologies: the increasingly prevalent plug fan and the traditionally robust centrifugal fan. This article provides an in-depth, technical comparison of plug fans versus centrifugal fans for data center AHU applications. Aimed at HVAC engineers, original equipment manufacturers (OEMs), data center designers, and facility managers, this analysis will delineate the operational principles, performance characteristics, and ideal use cases for each technology. The goal is to furnish stakeholders with the nuanced understanding necessary to select the optimal solution that aligns with specific project requirements for efficiency, reliability, and long-term scalability.

Understanding the Unique Demands of Data Center AHUs

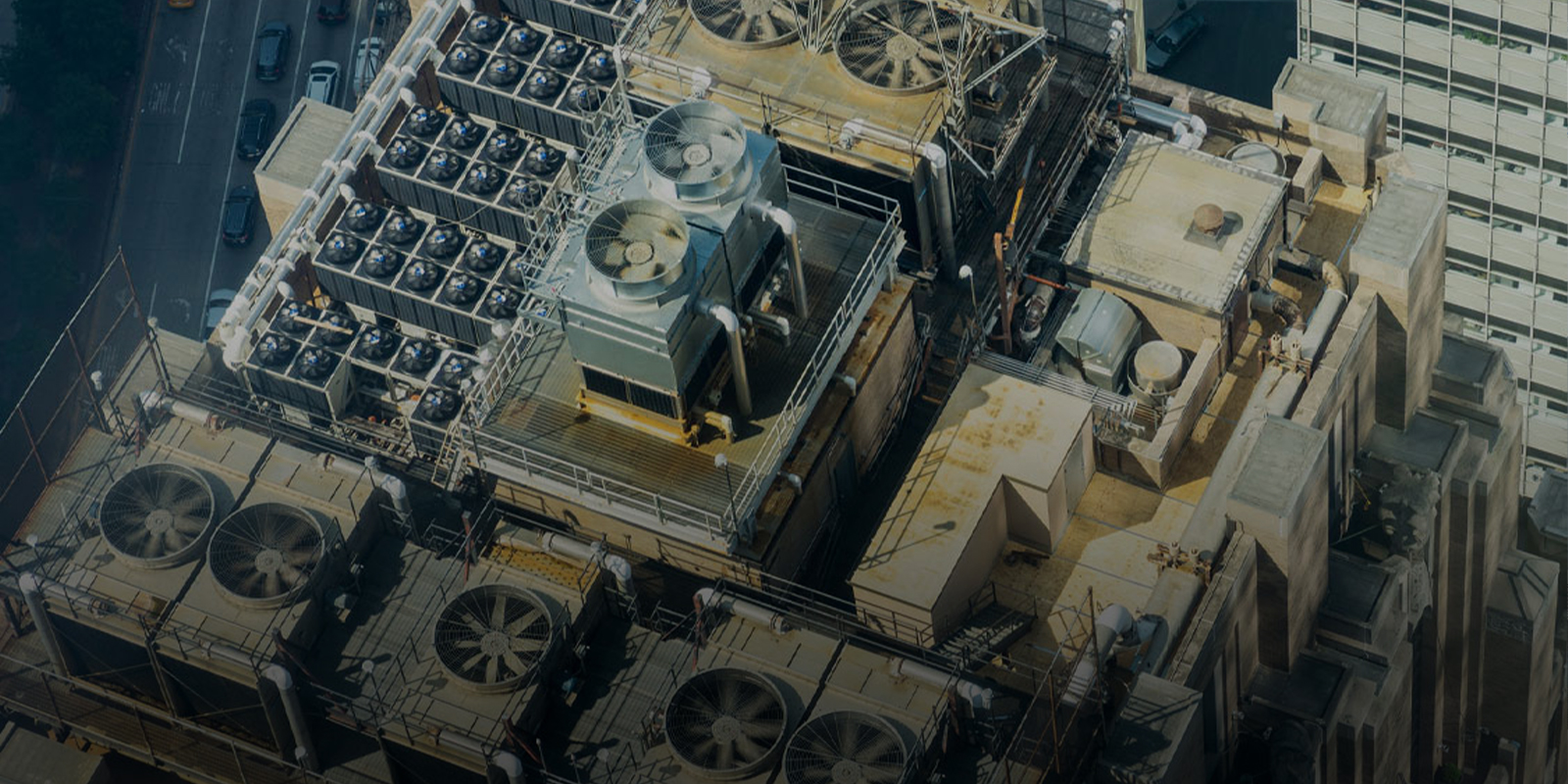

Data center cooling systems operate under a set of constraints that distinguish them sharply from typical commercial HVAC applications. These environments demand continuous, 24/7 operation with essentially zero tolerance for cooling interruptions, translating to a requirement for exceptional fan reliability and built-in redundancy. The thermal load is both high and dynamic, fluctuating with IT workload, which necessitates fans capable of precise modulation across a wide range of airflow rates while maintaining stable static pressure. Furthermore, the push for greater power usage effectiveness (PUE) places a premium on fan efficiency, particularly at part-load conditions which represent the most common operational state. Airflow must be uniform and predictable to prevent hot spots, and the physical footprint of cooling equipment is often scrutinized to maximize white space for servers. Both plug fans and centrifugal fans are engineered to meet these challenges, but their inherent design philosophies lead to different performance profiles and integration strategies.

Defining the Technologies: Principles of Operation

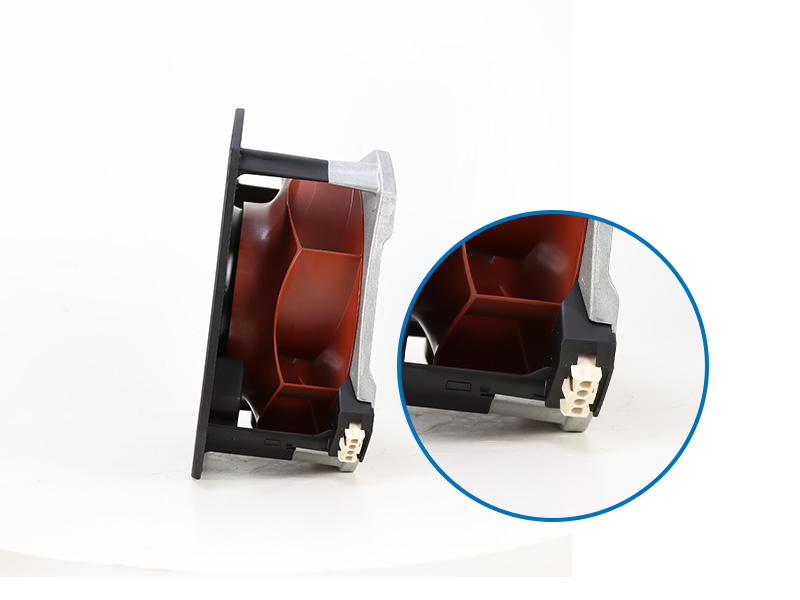

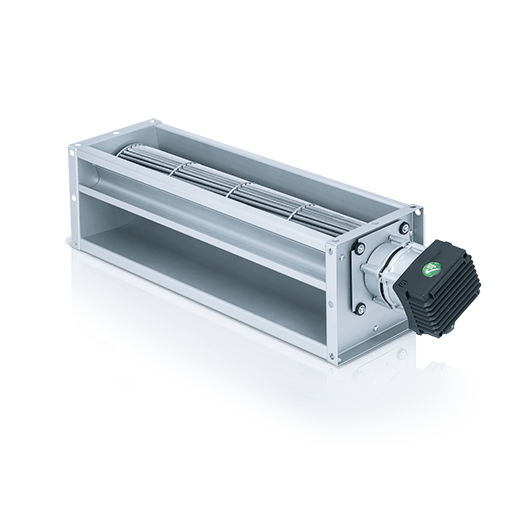

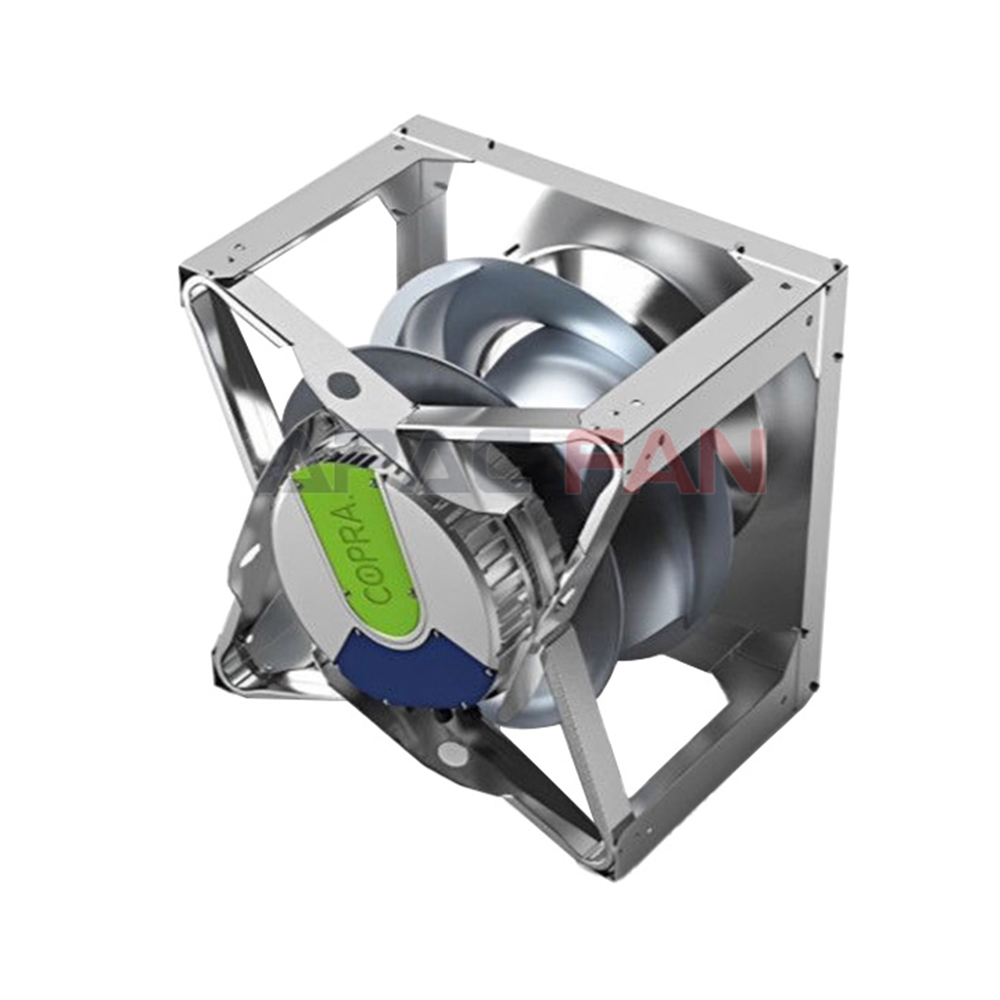

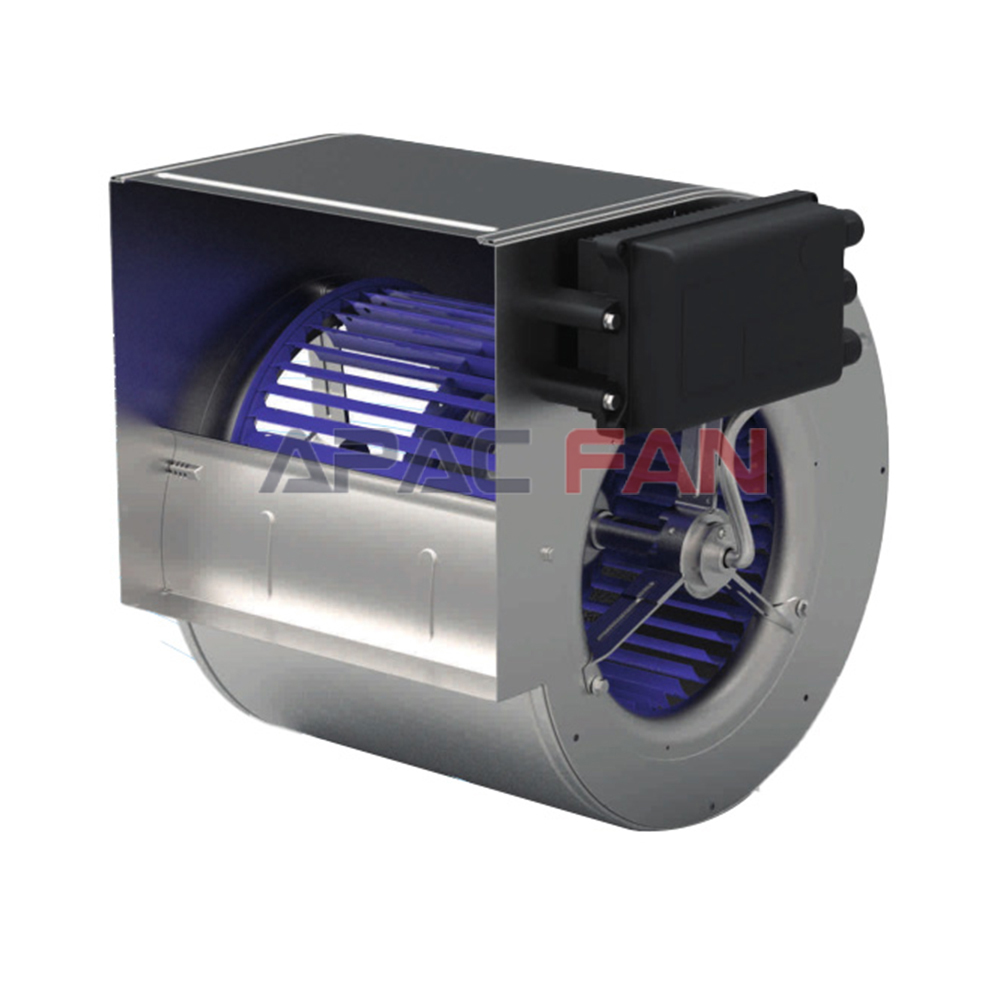

What is a Plug Fan?

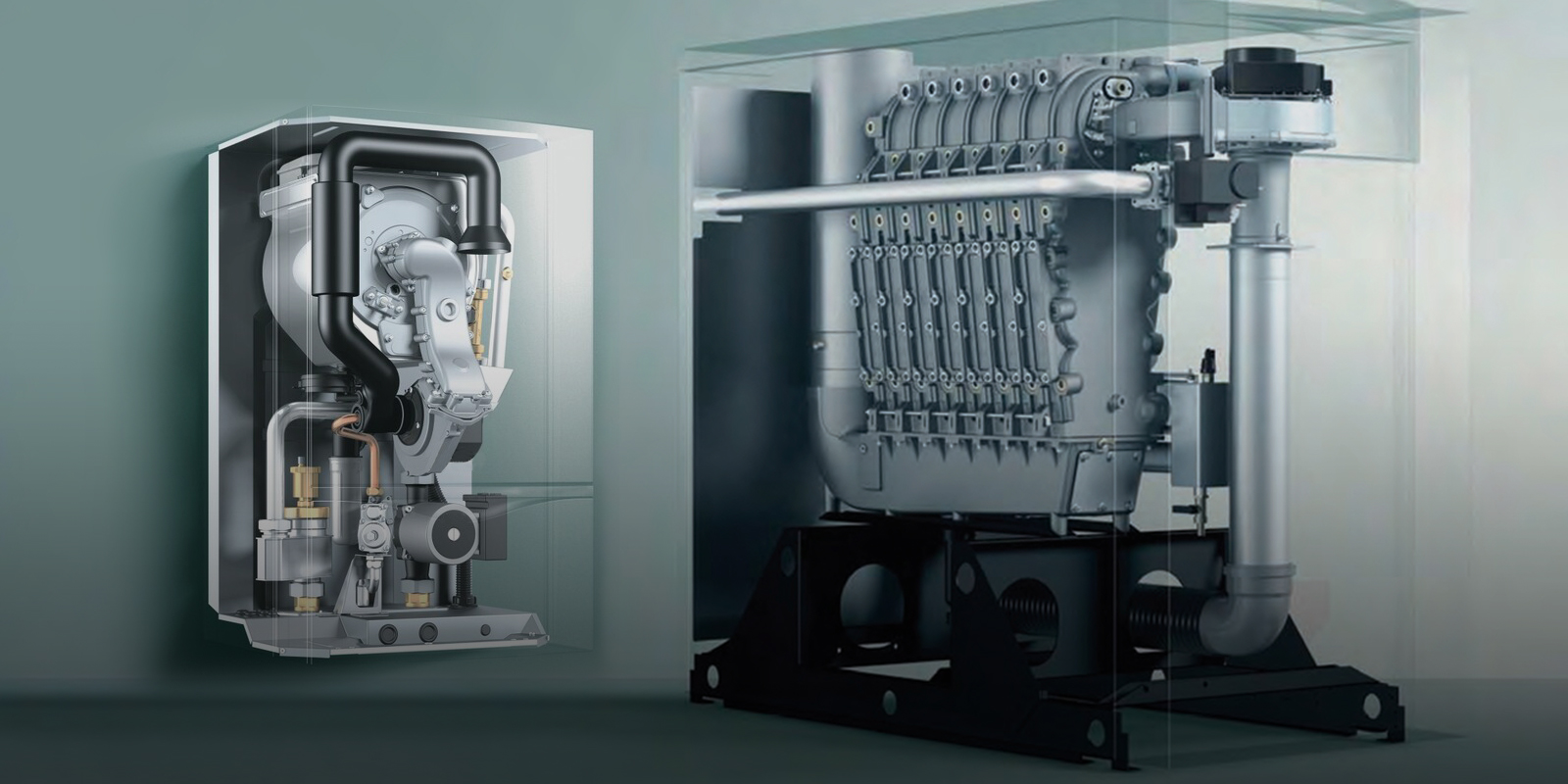

A plug fan, also known as a plug-type or plenum fan, is characterized by its integration of a motorized impeller—typically a backward-curved or airfoil design—that is installed directly into the wall of the AHU plenum chamber, operating without a traditional scroll or venturi housing. The motor, often a high-efficiency Electronically Commutated (EC) motor, is mounted directly to the impeller, creating a compact, self-contained aerodynamic unit. Air is drawn axially into the impeller and discharged radially directly into the plenum, which then directs the airflow into the duct system or raised floor void. This housing-less design allows for a remarkably compact form factor and enables the creation of "fan wall" or array configurations, where multiple plug fans are installed in a grid pattern on a single plenum wall.

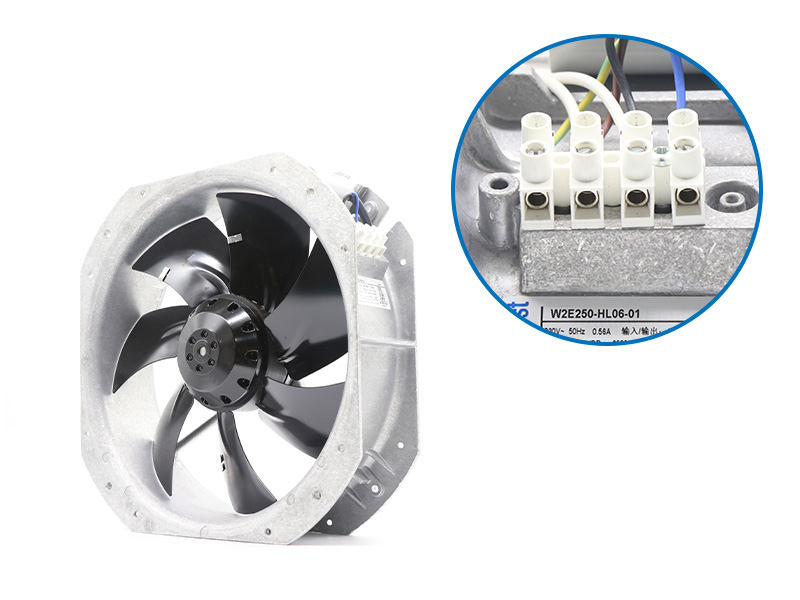

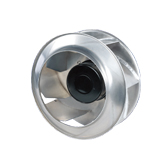

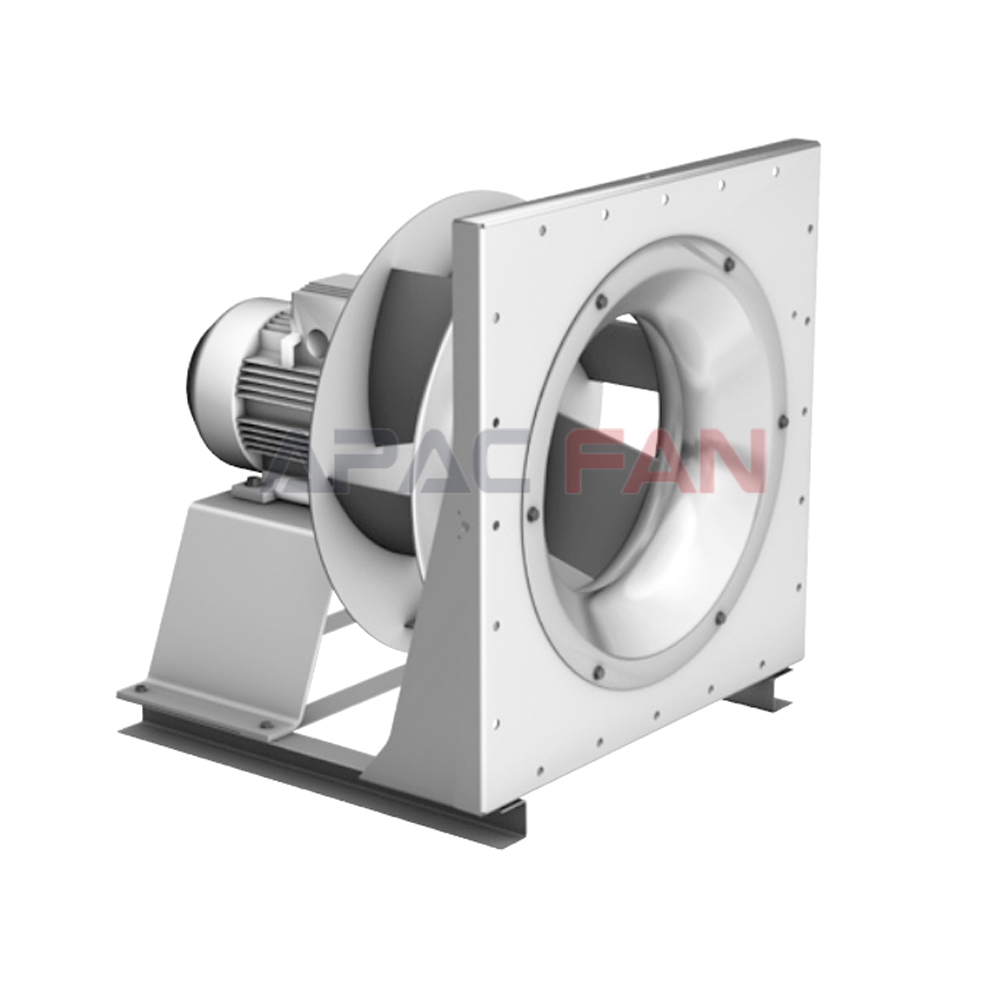

What is a Centrifugal Fan?

The centrifugal fan is a time-tested technology familiar across countless HVAC applications. In a centrifugal fan, the impeller (again, often backward-curved for efficiency in AHU service) is housed within a scroll-shaped casing. Air enters the impeller eye axially, is accelerated radially by centrifugal force, and is discharged into the volute or scroll housing. This housing acts as a diffuser, efficiently converting kinetic energy into static pressure, and guides the airflow to the outlet. Centrifugal fans in AHUs are typically powered by AC induction motors, either connected via belts and sheaves or, in more modern designs, coupled directly or using EC motors. The scroll housing defines a predictable airflow path and is responsible for the fan's ability to develop high static pressure.

Performance Comparison: A Multi-Dimensional Analysis

1. Energy Efficiency and Part-Load Performance

This is often the most critical differentiator for data centers focused on operational expenditure (OpEx).

Plug Fans: Their synergy with integrated EC motor technology is a key advantage. EC motors are inherently variable speed and exhibit exceptionally high efficiency across a broad speed range, particularly at the reduced speeds typical of part-load operation. In a fan wall configuration, an advanced control system can sequence fans on and off and modulate the speed of those operating, ensuring each runs near its optimal efficiency point. This can lead to significant power savings, especially in climates with low ambient temperatures or in facilities with substantial load diversity.

Centrifugal Fans: A well-selected backward-curved centrifugal fan can achieve peak efficiencies comparable to, or even slightly exceeding, a plug fan at its designed Best Efficiency Point (BEP). However, its performance curve is steeper. When system resistance differs from the design point, or when the fan is throttled to lower speeds via inlet guide vanes or variable frequency drives (VFDs) on AC motors, the efficiency can drop more noticeably than with an EC-driven plug fan. For a data center with a constant, stable load, a centrifugal fan can be supremely efficient. For the more common variable load scenario, the plug fan array often holds an advantage in seasonal energy performance.

2. Airflow, Pressure Capability, and System Effects

Plug Fans: These fans excel in delivering high volumes of air at low to moderate external static pressures. Their performance is more susceptible to the conditions immediately at the inlet and outlet; a disrupted airflow profile at the inlet can affect performance. In a properly designed plenum with straight, unobstructed airflow into the fan inlet, they perform excellently. They are the standard for fan-wall-style AHUs that discharge directly into a large plenum or a raised floor, where system resistance is primarily from the floor tiles and IT racks.

Centrifugal Fans: The scroll housing makes centrifugal fans inherently more robust in overcoming higher system resistance. They are the preferred choice for applications requiring high static pressure, such as systems with long duct runs, multiple duct turns, high-efficiency particulate air (HEPA) filters, or other significant pressure drops in the airflow path. Their performance is more predictable and less sensitive to nearby obstructions, making them suitable for compact AHU designs with limited intake and discharge straight-run opportunities.

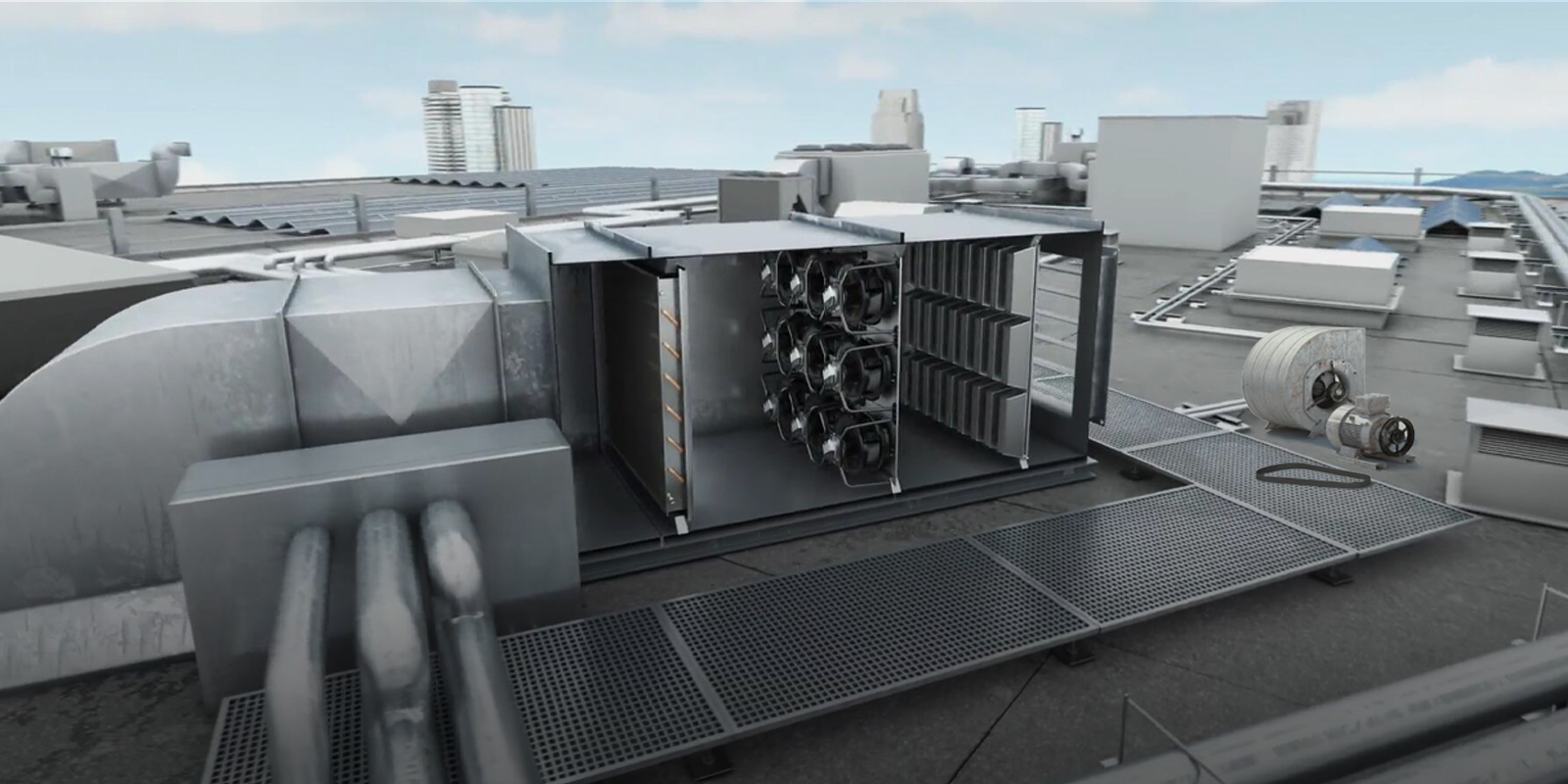

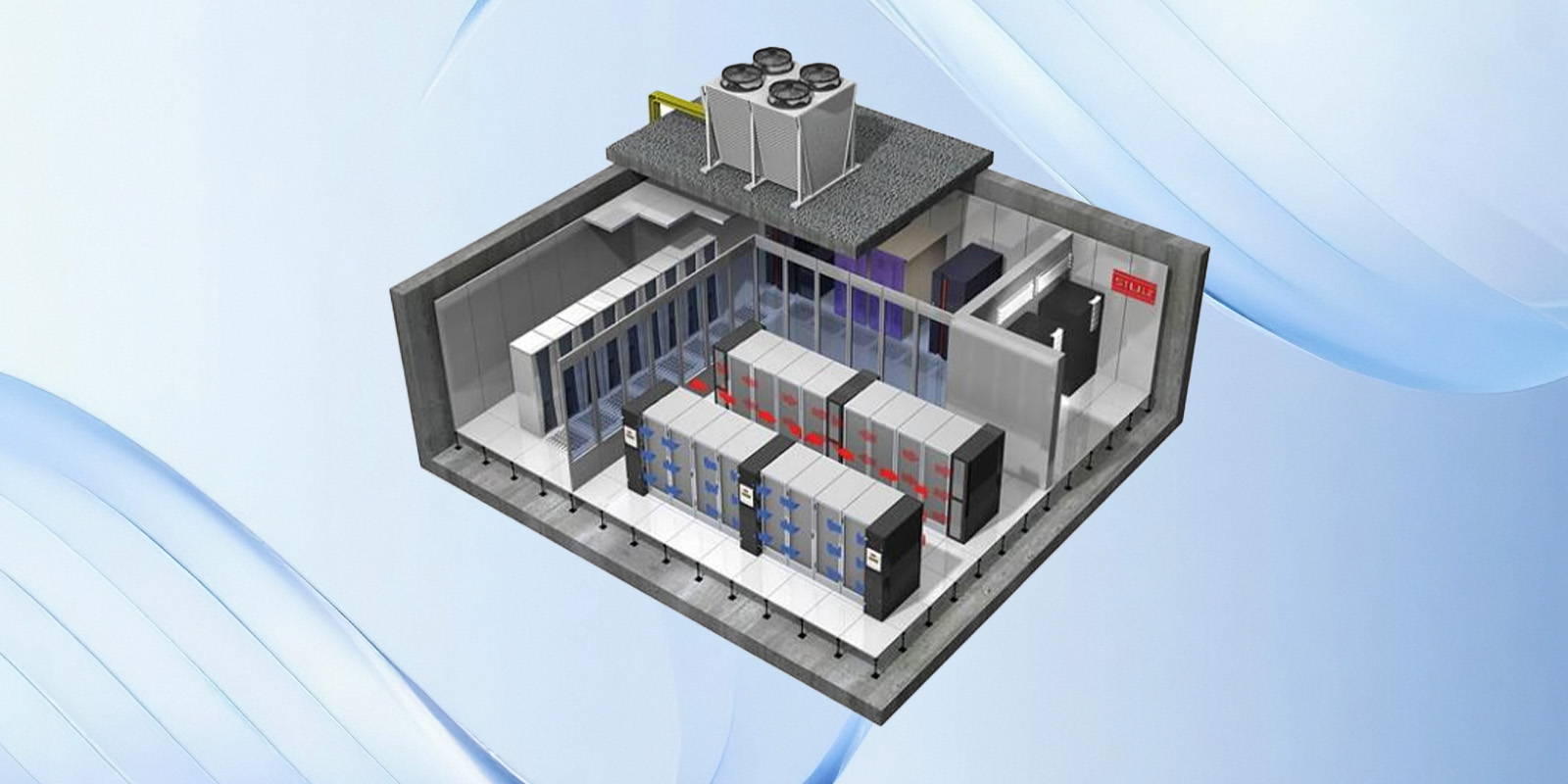

3. Redundancy, Availability, and Scalability

Plug Fans: This is where plug fan arrays demonstrate a transformative advantage for mission-critical facilities. An N+1, N+2, or even greater redundancy is achieved simply by installing extra fans in the wall. If a single fan module fails, the control system can increase the speed of the remaining fans to maintain airflow, and the failed unit can often be hot-swapped without shutting down the AHU. This facilitates maintenance without impacting cooling capacity. Scalability is also simplified; future capacity upgrades can sometimes be addressed by adding more fan modules to the existing wall.

Centrifugal Fans: Redundancy in centrifugal fan systems typically requires a complete duplicate fan and motor assembly (a full 100% standby unit). While reliable, a failure of the primary unit necessitates a transfer to the standby unit, which, while automatic, is a more significant system transition. Maintenance usually requires taking the entire fan assembly offline. Scalability is generally achieved by adding a complete new AHU or fan system rather than modularly expanding an existing one.

4. Installation, Footprint, and Maintenance

Plug Fans: The compact, modular nature of plug fans allows for a more flexible and space-efficient AHU design. The absence of bulky scroll housings reduces the overall unit footprint. Installation is generally simpler, as the fan module is a single unit mounted into a prepared opening. Maintenance involves dealing with a smaller, more manageable component. However, in an array, there are more individual units to potentially service.

Centrifugal Fans: These units require more space due to the scroll housing. Installation is more traditional and may involve aligning motors, belts, and sheaves for non-direct-drive models. Maintenance procedures are well-established in the industry. While a single centrifugal fan may have more components (belts, bearings, sheaves) that require maintenance, there are fewer total points of failure in a system with one or two large fans versus dozens of smaller plug fans.

5. Acoustics and Noise Generation

Plug Fans: The acoustic profile of a plug fan array is often characterized by a lower sound pressure level at part-load conditions due to the lower speed of the EC motors. However, because they operate in a free plenum, the overall acoustic performance is highly dependent on the internal design of the AHU, including the use of acoustic liners and the configuration of the fan wall. At full load, an array can generate significant broadband noise.

Centrifugal Fans: The scroll housing tends to contain and shape the noise signature, often making it more predictable and somewhat easier to attenuate with standard silencers. The low-frequency sound generated by larger centrifugal fans can be a consideration for structural transmission. Both technologies, when properly selected and housed within a well-designed AHU with appropriate acoustic treatment, are capable of meeting strict data center noise criteria, which typically focus on preventing vibration transfer to sensitive areas rather than occupant comfort.

The Role of Advanced Motor Technology: The Rise of EC

A discussion of modern fans is incomplete without addressing motor technology. The adoption of Electronically Commutated (EC) motors is a game-changer for both fan types, though it is almost ubiquitous in plug fans. EC motors offer integrated variable speed control, high full- and part-load efficiency, and advanced connectivity for system integration. For centrifugal fans, the shift from traditional AC motors with VFDs to EC motors (in direct-drive configurations) eliminates belts, reduces maintenance, and improves part-load efficiency, narrowing the performance gap with plug fan arrays in some applications.

Typical Use Cases and Application Guidelines

Plug Fans are typically the preferred solution for:

- New construction of large hyperscale or enterprise data halls.

- Modular data center designs and containerized solutions.

- Applications where seamless, modular redundancy (N+1) is a primary requirement.

- Retrofit projects where AHU footprint is limited.

- Systems designed for wide-range variable airflow control and premium part-load efficiency.

Centrifugal Fans remain the ideal choice for:

- AHUs requiring to overcome high static pressure from extensive ductwork, fluid coolers, or stringent filtration.

- Traditional built-up AHU systems where the design is centered on a few large air movers.

- Retrofits into existing infrastructure originally designed for centrifugal fan performance curves.

- Applications with space constraints that are better served by a single, powerful fan rather than a wall of multiple units.

- Environments where predictable acoustics and a proven, familiar technology are prioritized.

Conclusion: A Matter of Strategic Fit

There is no universal "best" fan for all data center AHU applications. The decision between plug fans and centrifugal fans is a strategic one, contingent upon specific project goals and constraints.

Plug fan arrays, with their modularity, inherent redundancy, and superior part-load efficiency through EC integration, represent a forward-looking solution optimized for the dynamic, scalable, and efficiency-driven world of modern hyperscale and large enterprise data centers. They offer unparalleled availability and operational flexibility.

Centrifugal fans, a robust and deeply understood technology, continue to offer exceptional performance, high-pressure capability, and predictable operation. They are often the optimal choice for complex ducted systems, high-static applications, or projects where the design paradigm and infrastructure favor a centralized fan approach.

Ultimately, the informed selection process must weigh the relative priority of key factors: static pressure requirements, redundancy strategy, part-load operational profile, physical footprint, and total cost of ownership. By meticulously evaluating these parameters against the inherent strengths of each fan technology, data center developers and operators can specify an AHU fan solution that delivers the precise balance of reliability, efficiency, and adaptability required to support the critical compute infrastructure within. Leading manufacturers like ebm-papst, by offering high-performance, reliable versions of both technologies, empower engineers and OEMs to make this choice based on pure technical merit and project fit, ensuring the cooling system acts as a resilient and efficient enabler of data center operations.

English

English Français

Français Deutsch

Deutsch Português

Português Español

Español русский

русский  한국어

한국어 العربية

العربية Italiano

Italiano Indonesia

Indonesia Schweiz

Schweiz Polski

Polski Nederlands

Nederlands ישראל - עברית

ישראל - עברית Perzisch

Perzisch ไทย

ไทย 日本語

日本語 ኢትዮ-አማርኛ

ኢትዮ-አማርኛ Việt Nam

Việt Nam Kiswahili

Kiswahili Srpski

Srpski Ελληνικά

Ελληνικά 繁體中文

繁體中文