Analysis of the Differences Between Condensers and Dry Coolers and the Application Advantages of ebm-papst AxiBlade Axial Fans

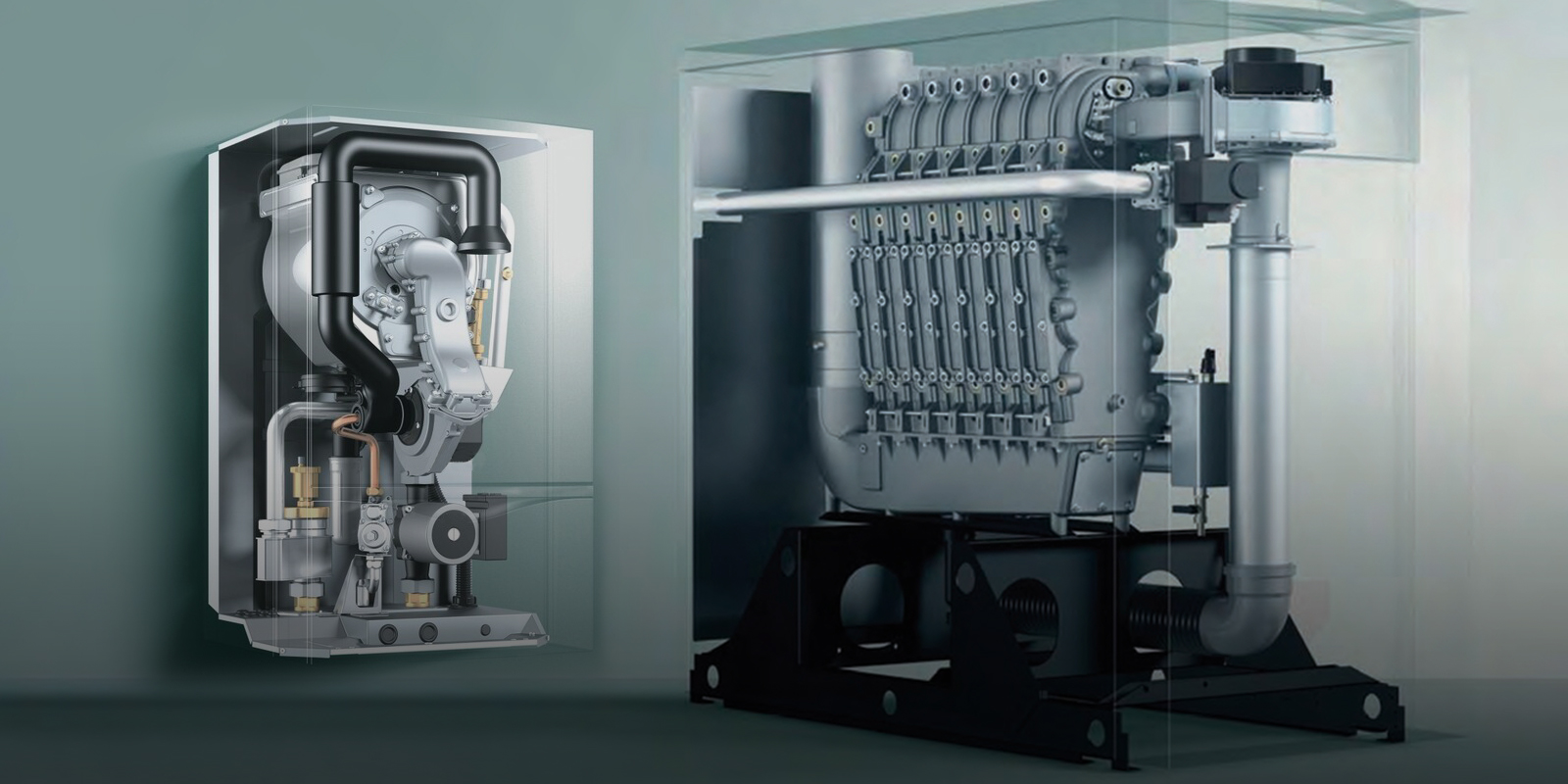

09/04/2025Condensers and dry coolers are two core components of cooling and refrigeration systems. While both perform heat exchange and temperature control, they differ significantly in their operating principles, core characteristics, and applicable scenarios, directly impacting the system's cooling efficiency, environmental friendliness, and adaptability. Furthermore, as a key auxiliary component driving heat exchange between these two types of equipment, the performance of the fan directly determines the overall performance of the cooling system. This article will detail the core differences between condensers and dry coolers and explain the key advantages of ebm-papst AxiBlade axial fans in both applications, providing a reference for cooling system selection and optimization.

Core Differences Between Condensers and Dry Coolers

(I) Operating Principles

- Condenser: The Heat Exchange Core Relying on Phase Change

As a key component of a refrigeration system, the condenser's core function revolves around phase change cooling: its primary task is to convert the gaseous refrigerant generated in the refrigeration cycle into liquid. The specific process is as follows: As the gaseous refrigerant flows through the condenser's internal channels, it continuously releases the heat it carries. This heat is then transferred to the external cooling medium (either air or water) through the condenser's heat exchange structure. Ultimately, after completing the heat exchange, the refrigerant undergoes a phase transition from gas to liquid, paving the way for the subsequent refrigeration cycle.

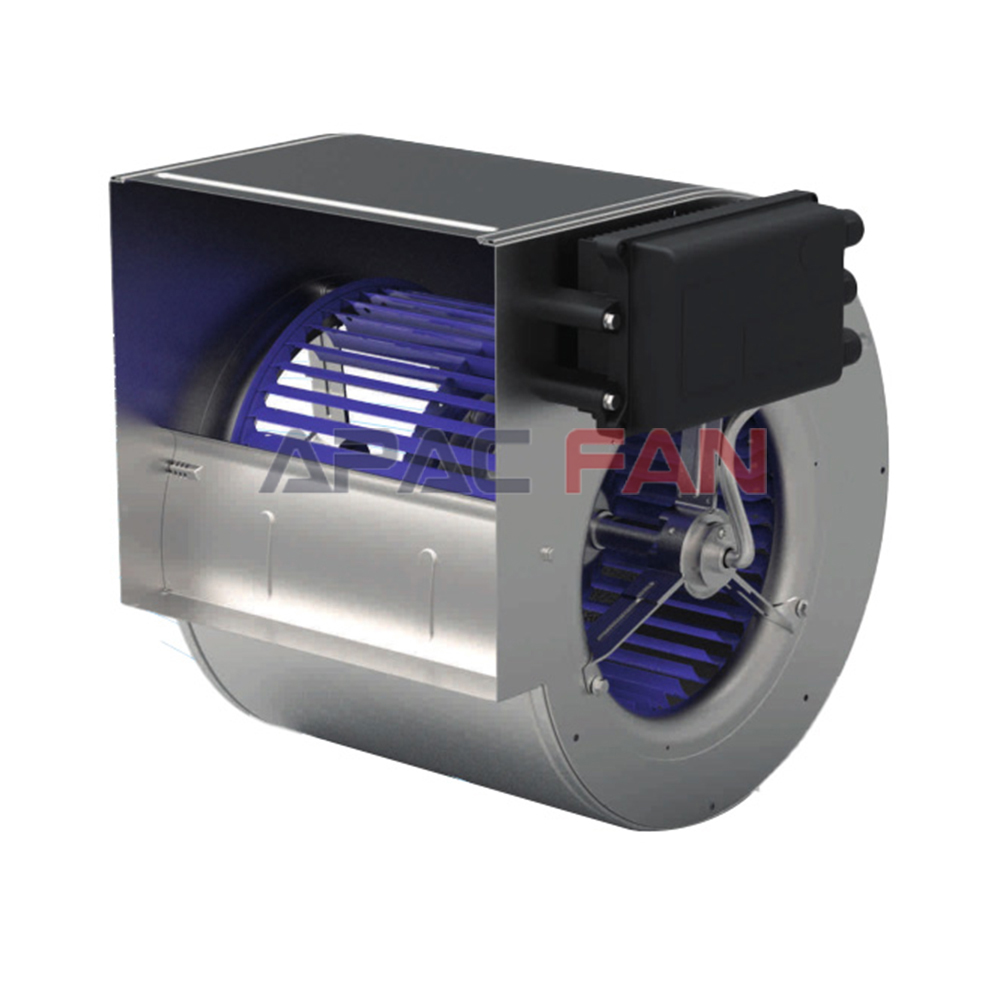

Depending on the cooling medium, condensers are primarily divided into two categories:

Air-cooled condensers: Ambient air is introduced through an accompanying fan, directly contacting the condenser's heat exchange tubes and removing heat from the refrigerant, eliminating the need for additional water.

Water-cooled condensers: Water is used as the cooling medium and are typically used in conjunction with a cooling tower. After absorbing the refrigerant's heat within the condenser, the cooling water is then transported to the cooling tower for cooling. The cooled water is then recirculated back to the condenser, creating a closed-loop cooling system.

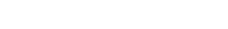

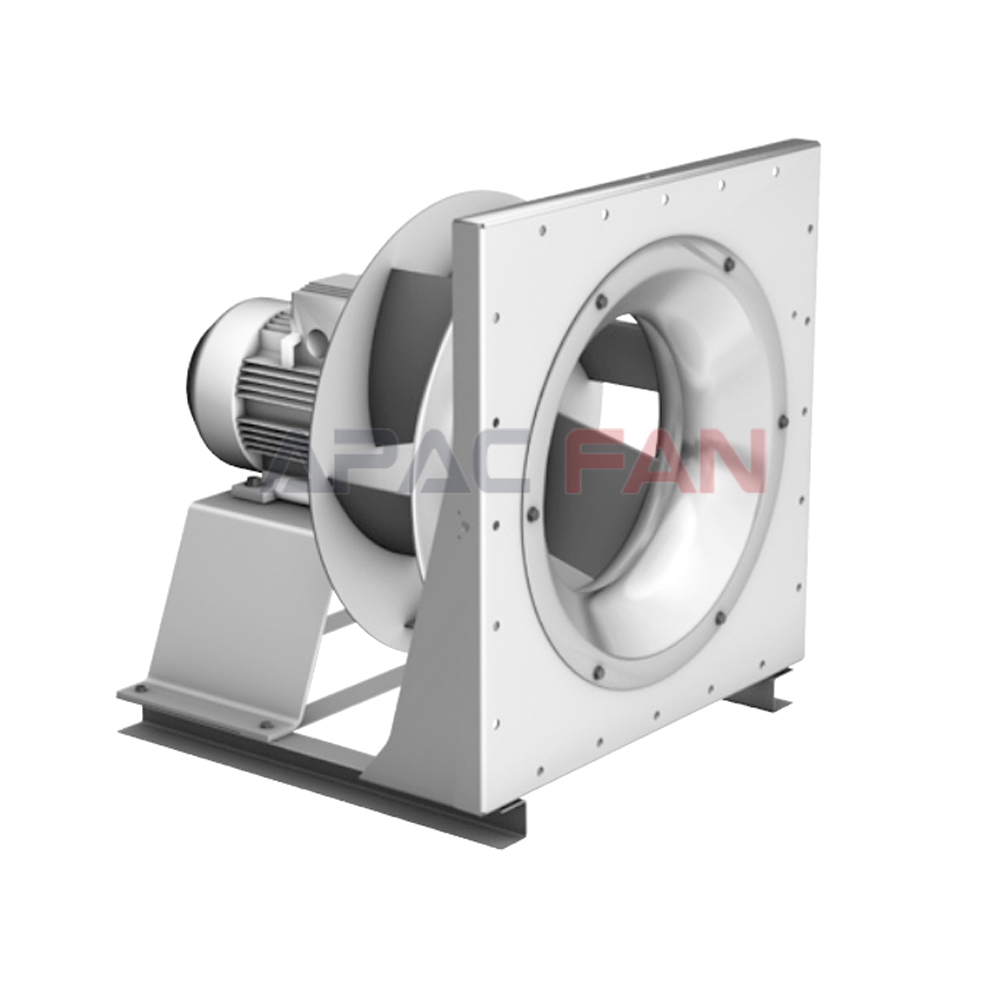

- Dry coolers: Direct air cooling devices without phase change

Dry coolers operate based on direct air cooling, without any phase change involved. The process works as follows: The fan built into the dry cooler draws ambient air into the device, where it comes into contact with the circulating fluid in the heat exchanger (mostly a mixture of water and ethylene glycol, suitable for anti-freezing in low-temperature environments). Through heat exchange, the air removes heat from the fluid, lowering its temperature. The cooled fluid is then re-delivered to the equipment requiring cooling (such as servers and industrial units), completing the cooling cycle.

(II) Application Scenario Adaptation

- Condenser: An Essential Component for Efficient Refrigeration Systems

The condenser's application scenarios are highly focused on systems requiring stable and efficient cooling, specifically including:

Refrigeration Cycle-Related Fields: Commercial Refrigeration (such as supermarket refrigerators and commercial cold storage), Industrial Refrigeration (such as chemical production cooling and precision equipment cooling);

Air Conditioning Systems: The refrigeration module in residential and commercial central air conditioners is the core component for ensuring indoor temperature control.

The condenser's core advantage lies in its high heat exchange efficiency, which can meet high-load cooling demands. It is an indispensable component in cooling systems that rely on refrigerant circulation. 2. Dry Coolers: The "Preferred Solution" for Water-Saving and Environmentally Friendly Applications

Dry coolers are primarily used in refrigerant-free environments with clear water conservation or environmental protection requirements. Typical applications include:

Applications requiring refrigerant-free cooling: server cooling in data centers (requiring stable cooling without refrigerants), auxiliary cooling in industrial production (such as machine tool and motor cooling), and cooling fresh air systems in commercial buildings.

Applications suitable for areas with limited water resources (such as arid regions) and projects with strict restrictions on environmental emissions or water consumption (such as green buildings and ecological parks) can avoid the water consumption and wastewater treatment issues associated with water cooling.

Advantages of ebm-papst AxiBlade Axial Fans

Whether it is air heat exchange in the condenser or air intake in the dry cooler, fan performance directly impacts the cooling efficiency and operational stability of the equipment. The ebm-papst AxiBlade axial flow fan offers five core advantages tailored to the operational needs of two types of equipment:

- High Energy Efficiency: Drive system energy efficiency upgrades

This fan boasts an overall operating efficiency of up to 60%, precisely matching the heat exchange requirements of condensers and dry coolers. This efficient air delivery enhances the heat exchange between the refrigerant or circulating fluid and the air, improving not only the cooling performance of a single unit but also the energy efficiency of the entire cooling system, reducing long-term energy consumption.

- Low Noise: Optimizing Ambient Acoustic Quality

Compared to its predecessor, the AxiBlade axial flow fan achieves a noise level reduction of up to 8 dB(A). This optimization significantly reduces ambient noise during operation, making it particularly suitable for acoustically sensitive environments such as data centers, commercial buildings, and residential areas, ensuring a balanced cooling performance and environmental comfort.

- Durability: Adaptable to complex operating environments

The fan features a high-grade waterproof design and excellent corrosion resistance. Even in high-temperature, high-humidity, and dusty outdoor environments, or in industrial scenarios with minor chemical exposure (such as chemical cooling areas), it effectively resists external corrosion, ensuring long-term stable operation, extending service life, and reducing maintenance frequency and costs.

- Intelligent Speed Control: Matching Loads on Demand

The fan is equipped with a flexibly configurable control electronics module that supports bidirectional transmission of analog and digital signals. During operation, it automatically adjusts speed based on the cooling system's real-time load (such as the refrigerant temperature in the condenser and the fluid temperature in the dry cooler). High loads increase speed to enhance cooling, while low loads reduce speed to save energy, always keeping the equipment operating within its optimal efficiency range.

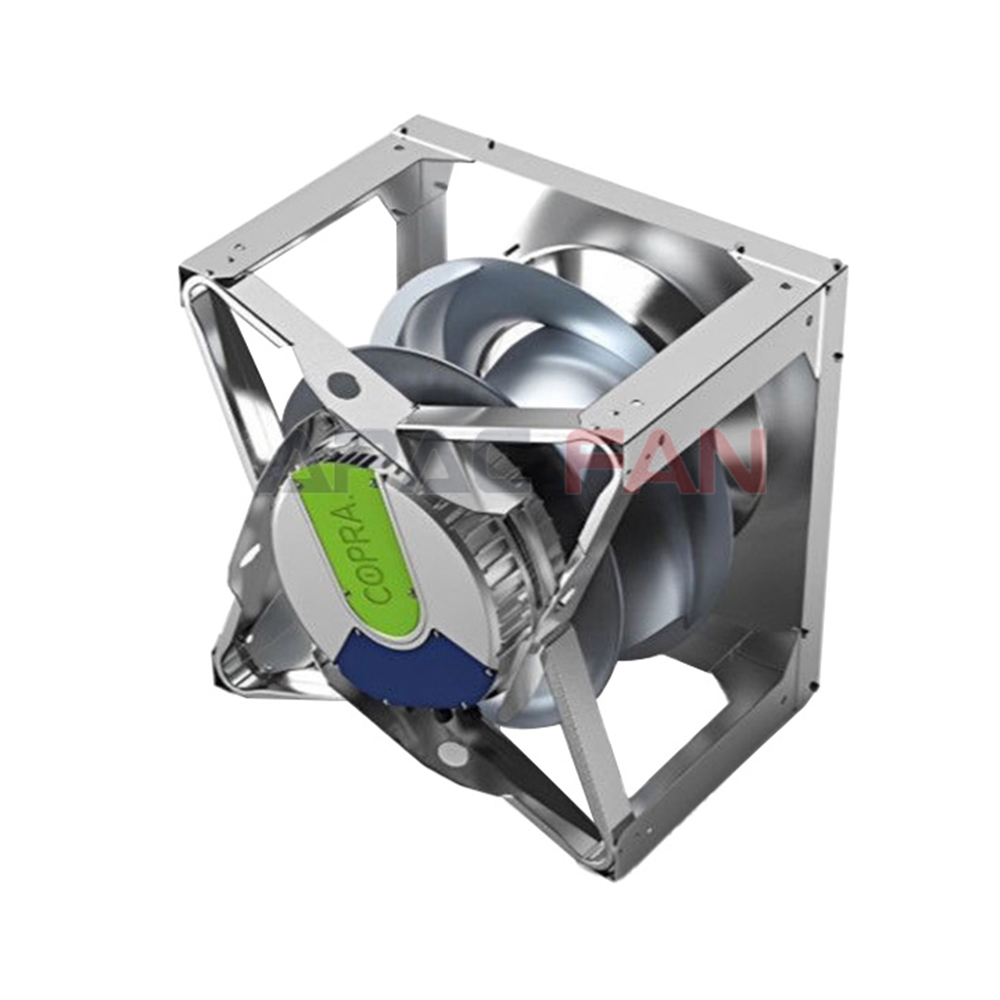

- Compact Design: Adaptable to Various Installation Scenarios

The "external rotor motor and impeller" integrated design creates a compact axial flow fan unit. This design not only simplifies the installation process of the fan, condenser, and dry cooler, but also significantly reduces equipment space, allowing for flexible adaptation to cooling equipment of varying sizes and confined installation environments (such as building ceilings and equipment room corners).

While condensers and dry coolers both serve cooling needs, their core differences, namely phase change cooling and direct air cooling, make them key choices for high-efficiency cooling systems and water-saving and environmentally friendly scenarios, respectively. The former ensures a stable and efficient refrigeration cycle, while the latter meets the cooling needs of low energy consumption and environmental protection. ebm-papst's AxiBlade axial flow fans, with their combined advantages of high energy efficiency, low noise, strong durability, intelligent speed regulation, and compact design, provide key support for the operation of both types of equipment. They maximize cooling performance while reducing energy consumption and maintenance costs, ultimately helping cooling systems achieve the goals of "high efficiency, stability, and environmental protection" in a variety of applications, including commercial, industrial, and architectural applications.

English

English Français

Français Deutsch

Deutsch Português

Português Español

Español русский

русский  한국어

한국어 العربية

العربية Italiano

Italiano Indonesia

Indonesia Schweiz

Schweiz Polski

Polski Nederlands

Nederlands ישראל - עברית

ישראל - עברית Perzisch

Perzisch ไทย

ไทย 日本語

日本語 ኢትዮ-አማርኛ

ኢትዮ-አማርኛ Việt Nam

Việt Nam Kiswahili

Kiswahili Srpski

Srpski Ελληνικά

Ελληνικά 繁體中文

繁體中文