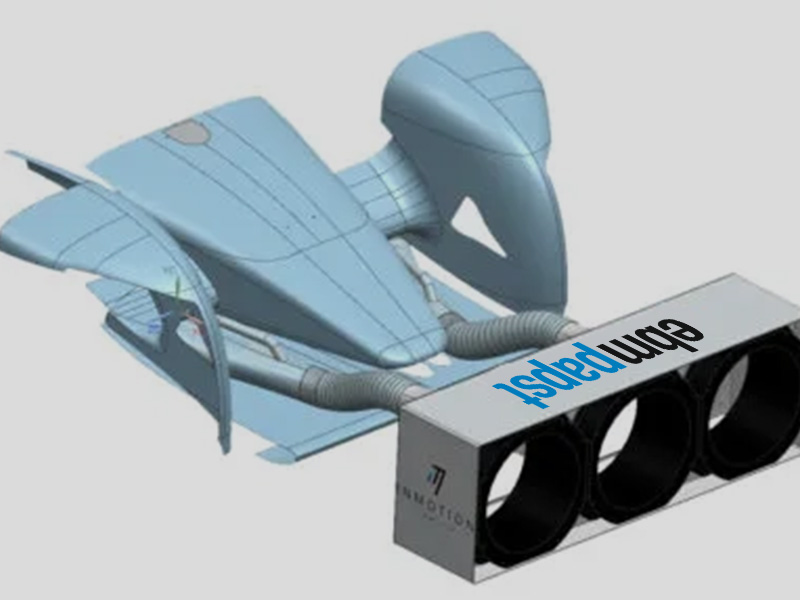

ebm-papst AxiEco Fan Powers InMotion's Electric Race Car

12/02/2025As electric racing technology advances at a rapid pace, efficient thermal management has become a core factor in enhancing vehicle performance and charging capabilities. The student team InMotion from Eindhoven, Netherlands, has integrated the ebm-papst AxiEco fan into its high-performance electric race car “Revolution,” delivering an innovative cooling solution that addresses critical battery thermal management under extreme operating conditions—and offering a valuable real-world case for the future of electric mobility.

The Need for Speed: Thermal Management as a Key Enabler

The name “Revolution” reflects its groundbreaking performance: the car accelerates from 0 to 100 km/h in just 6.5 seconds, with a top speed approaching 300 km/h. Power is supplied by a 57.6 kWh battery system, consisting of 30 modules with 12 cells each. However, the intense heat generated during high-power output and ultra-fast charging poses significant challenges to battery stability, service life, and safety. As the team targets a “refueling-like” charging experience—aiming to recharge the battery in just minutes—managing heat has become a central engineering priority.

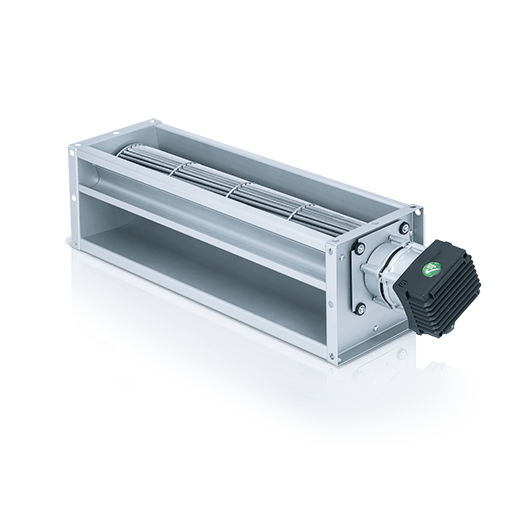

Under these conditions, traditional liquid cooling alone is often insufficient, particularly when the vehicle is stationary during charging and lacks ram air effect. A forced-air cooling system capable of delivering consistent, targeted airflow under high electrical load is essential to prevent overheating. The ebm-papst AxiEco axial fan was selected for its ability to maintain stable airflow even under high system pressure, and was integrated into Revolution’s dual cooling system alongside liquid cooling, forming a multi-layered thermal management barrier.

AxiEco Fan: Ensuring Reliability During Ultra-Fast Charging

During high-power charging, chemical reactions within the battery accelerate, generating concentrated heat. If not dissipated promptly, this can lead to reduced performance, slower charging rates, or even thermal runaway. This is especially critical when targeting a full charge within 7.5 minutes, where the battery must accept very high current in a very short time.

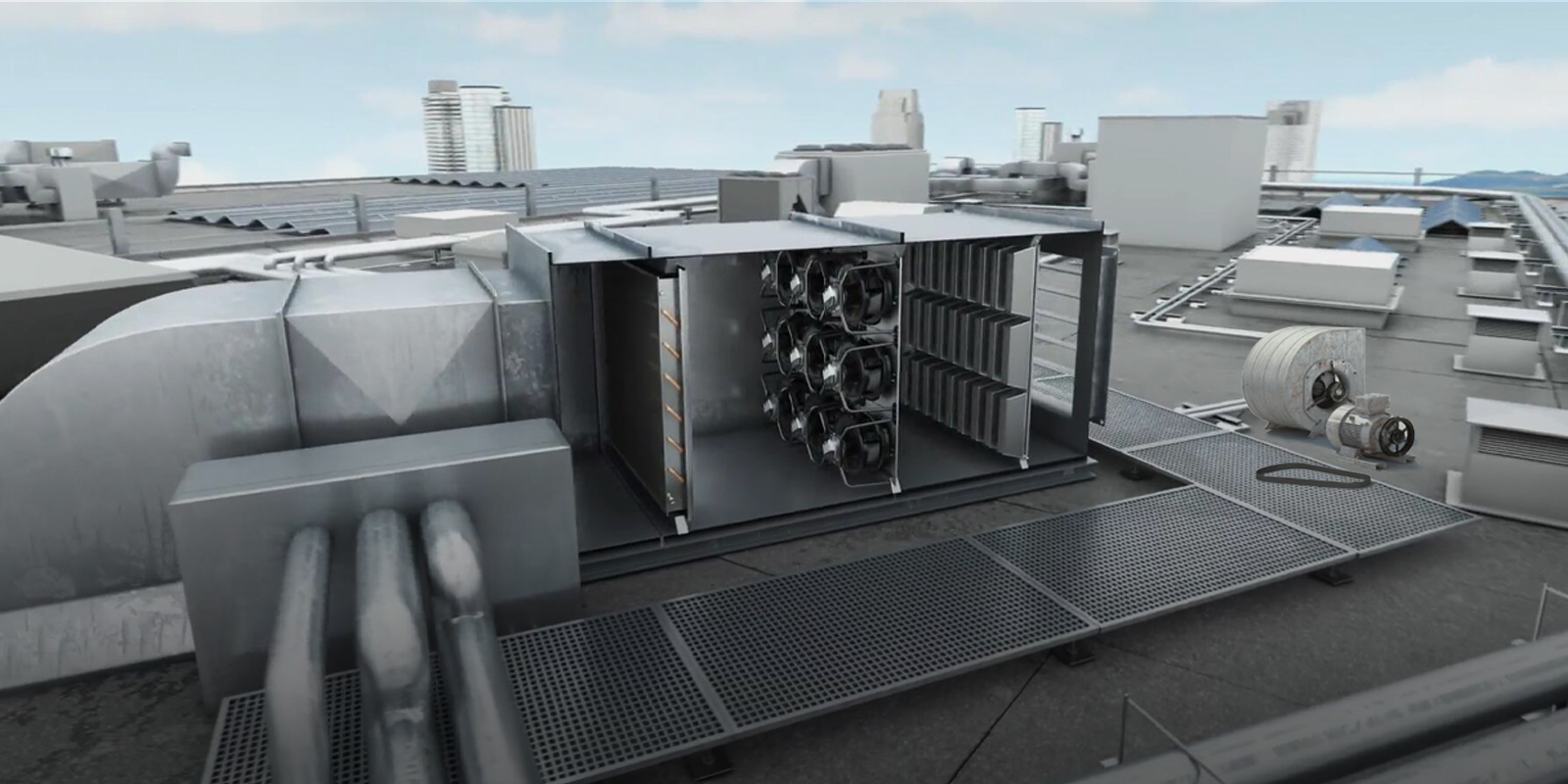

The AxiEco fan enhances convective heat transfer across the surface of the battery modules by delivering a consistent and directed airflow within a compact installation space. Its advanced impeller design and motor technology allow it to maintain airflow without significant drop-off, even when system resistance is high. This ensures even and efficient cooling for each cell—a level of stability under dynamic conditions that standard fans cannot match, and a key reason for its selection by the InMotion team.

In addition, the fan’s low noise, high energy efficiency, and compact form factor align with the vehicle’s lightweight and space-saving requirements. It operates reliably and quietly in all scenarios, whether the car is racing on the track or stationary during charging.

Industry-Academia Collaboration: Expanding the Boundaries of Innovation

ebm-papst actively supports university and student teams in the field of electric mobility, and the partnership with InMotion is a clear example of this commitment. Through regular communication and joint testing, ebm-papst not only supplied racing-optimized fan technology but also shared expertise in airflow dynamics and thermal management, helping the student team better integrate the fan into the overall vehicle system.

This industry-education collaboration not only accelerated the technical development of the Revolution race car but also provided young engineers with hands-on experience in tackling real engineering challenges—from thermal management and system integration to component selection. Many team members gained valuable skills that prepare them for future careers in electric vehicle development.

Implications for the Future of EV Thermal Management

The InMotion project demonstrates the feasibility and potential of hybrid air-liquid cooling systems under extreme performance demands. The successful application of the ebm-papst AxiEco fan in this setting highlights its adaptability to high-stress environments and offers a valuable reference for the broader electric vehicle industry.

As the demand for fast-charging capabilities grows, thermal management systems will increasingly become a key differentiator in EV design. With its extensive expertise in airflow and drive technology, ebm-papst continues to support global innovators in overcoming technical barriers—helping shape an electric mobility future that is safer, more efficient, and more reliable.

English

English Français

Français Deutsch

Deutsch Português

Português Español

Español русский

русский  한국어

한국어 العربية

العربية Italiano

Italiano Indonesia

Indonesia Schweiz

Schweiz Polski

Polski Nederlands

Nederlands ישראל - עברית

ישראל - עברית Perzisch

Perzisch ไทย

ไทย 日本語

日本語 ኢትዮ-አማርኛ

ኢትዮ-አማርኛ Việt Nam

Việt Nam Kiswahili

Kiswahili Srpski

Srpski Ελληνικά

Ελληνικά 繁體中文

繁體中文