ebm-papst Empowering Breakthroughs in Heating

12/03/2025Driven by the dual forces of energy structure transformation and escalating consumer demands, the heating industry is rapidly evolving from traditional small-scale wall-hung boiler systems to a comprehensive broad heating ecosystem encompassing heat pumps, air conditioners, and other multi-scenario applications. As a global leader in thermal technology R&D and application, ebm-papst has developed two core heating solutions, leveraging its profound industry insights to deliver efficient, sustainable technical support for diverse heating needs. These solutions empower clients to transition from single-function heating to integrated comfortable home systems.

Heat Pump-Specific Fan Solutions: Unlocking Sustainable Heating Pathways

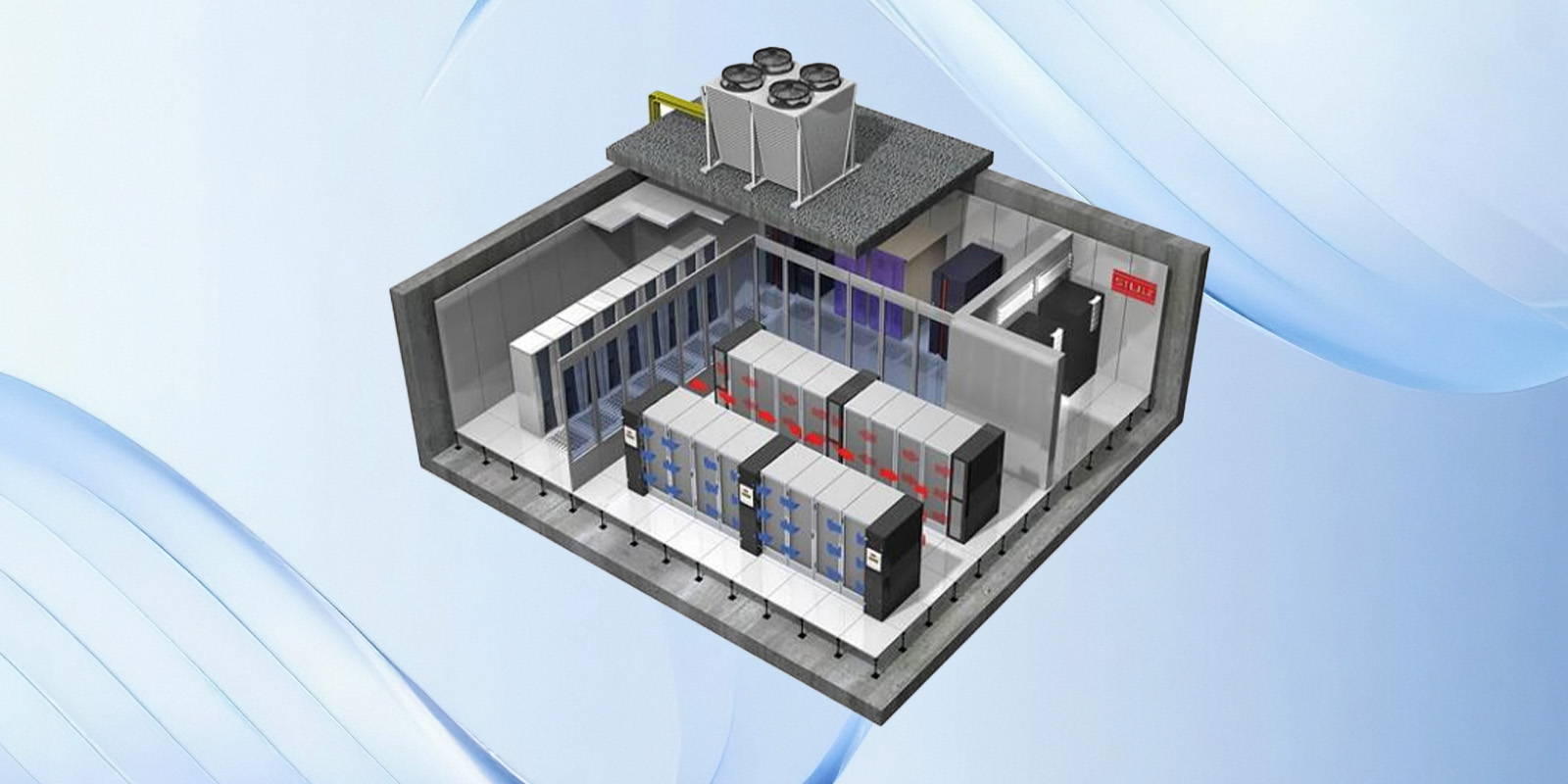

With the advancement of global carbon neutrality goals, heat pumps have emerged as the preferred heating choice for residential and multi-family buildings due to their safety, low carbon footprint, and high efficiency. Tailored to the operational characteristics of heat pump systems, ebm-papst’s dedicated fan solutions cater to various scenarios—from single-family homes to multi-unit apartments—providing reliable heat dissipation for core components such as heat pump water heaters and evaporators, and enhancing overall system energy efficiency at the source.

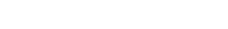

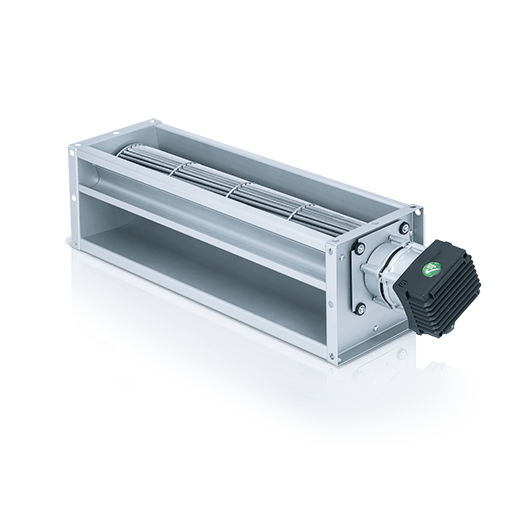

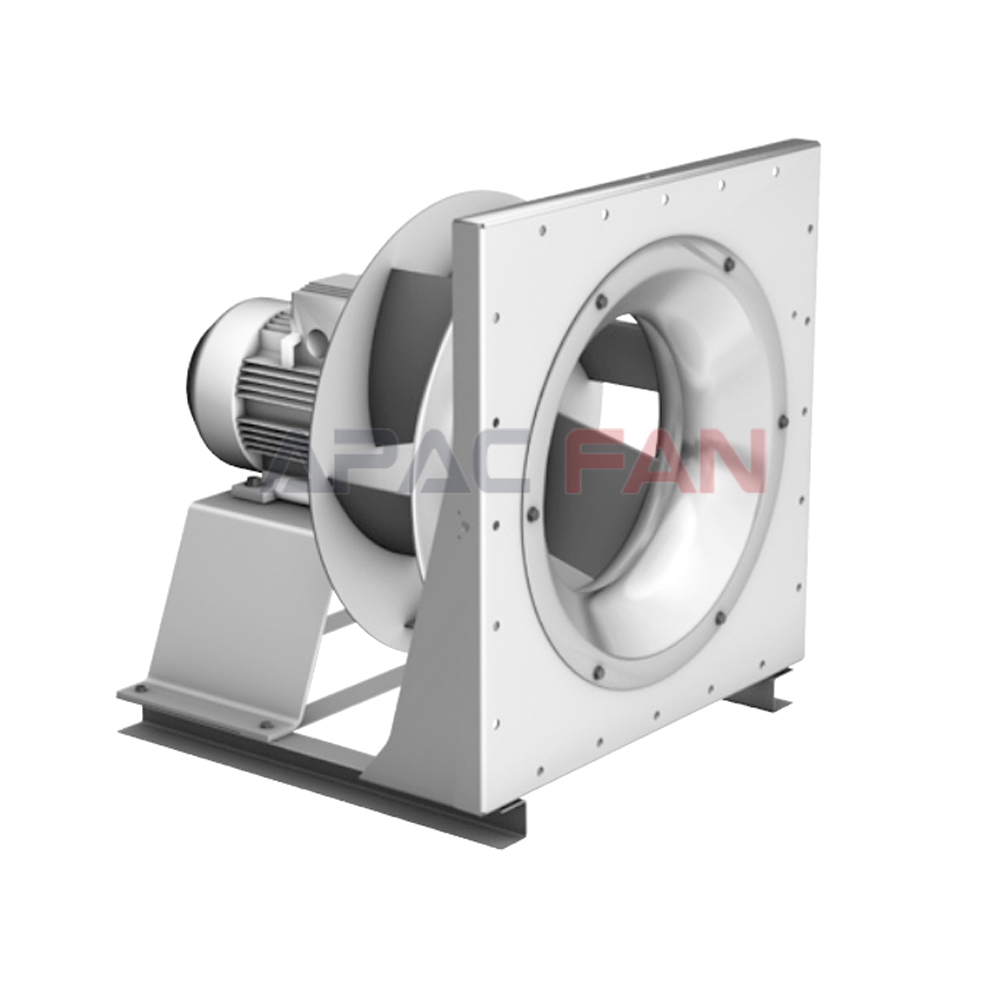

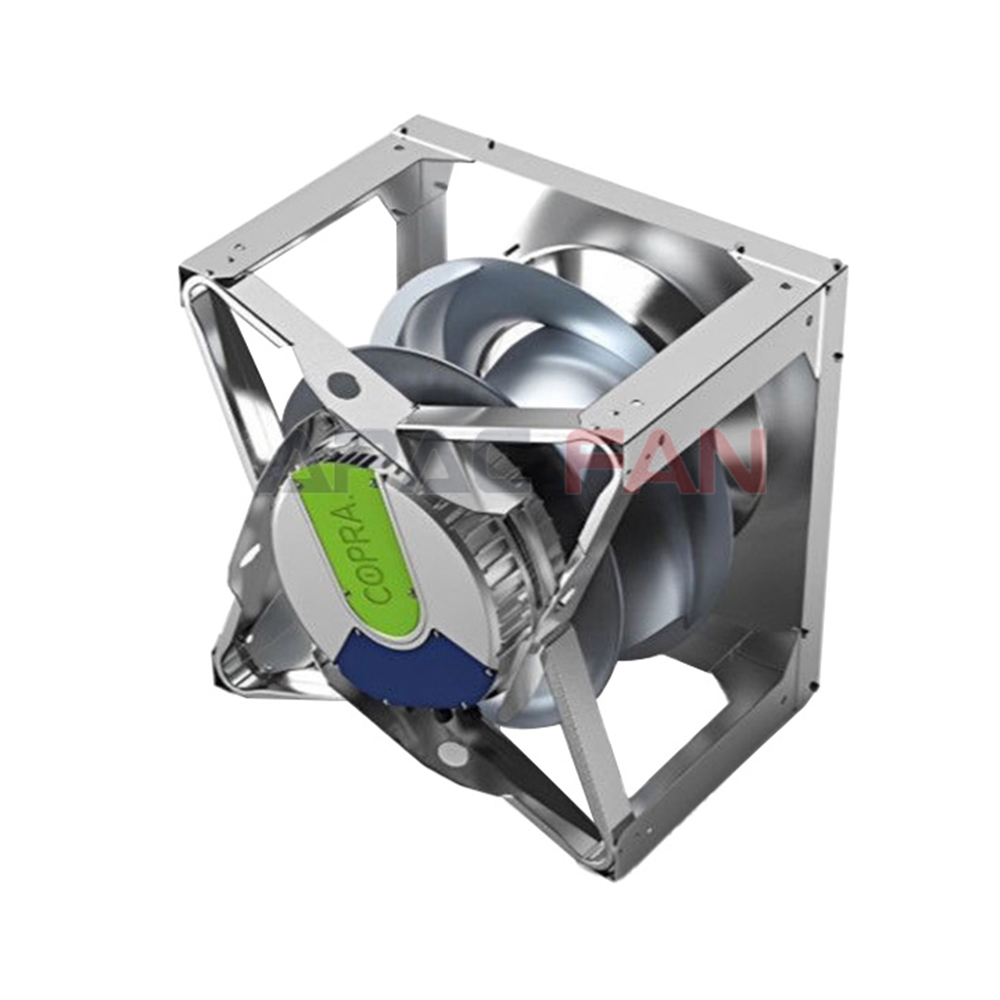

The solution comprises two product lines: centrifugal fans and axial fans, both engineered with the core design principles of "compact structure + high-performance operation." Centrifugal fans feature optimized impeller structures and airflow channels, delivering high static pressure within limited spaces. Even in complex heat pump pipelines, they efficiently dissipate heat generated by equipment operation, preventing overheating-related system instability. Axial fans, on the other hand, boast lightweight bodies and low-resistance blade designs, adapting to evaporators of different sizes. While ensuring optimal heat dissipation, they minimize space occupancy, seamlessly integrating into the installation layouts of various heat pump equipment.

Energy efficiency and low noise are standout advantages of ebm-papst’s heat pump fans. Equipped with quiet motors and shock-absorbing structures, the fans operate at ultra-low noise levels—well below industry standards—eliminating disruptions in residential environments, particularly in noise-sensitive areas like bedrooms and living rooms. Additionally, the fans incorporate intelligent speed control technology, automatically adjusting rotational speed based on real-time system load. During low-load operation, the fans reduce speed to cut energy consumption; during high-load operation, they increase speed to ensure heat dissipation, achieving "on-demand energy supply" and boosting heat pump energy efficiency by 15%-20%.

Crucially, ebm-papst offers end-to-end customization to meet individual client needs. Its technical team tailors fan parameters—including blade angle, motor power, and interface specifications—based on factors such as heat pump model, installation space, and heat dissipation requirements. For example, for heat pump systems in cold northern regions, fans are enhanced for low-temperature adaptability, ensuring stable startup even at temperatures below -20℃. For humid southern regions, fan components are treated with anti-corrosion coatings to extend service life, delivering truly "one equipment, one solution" customization.

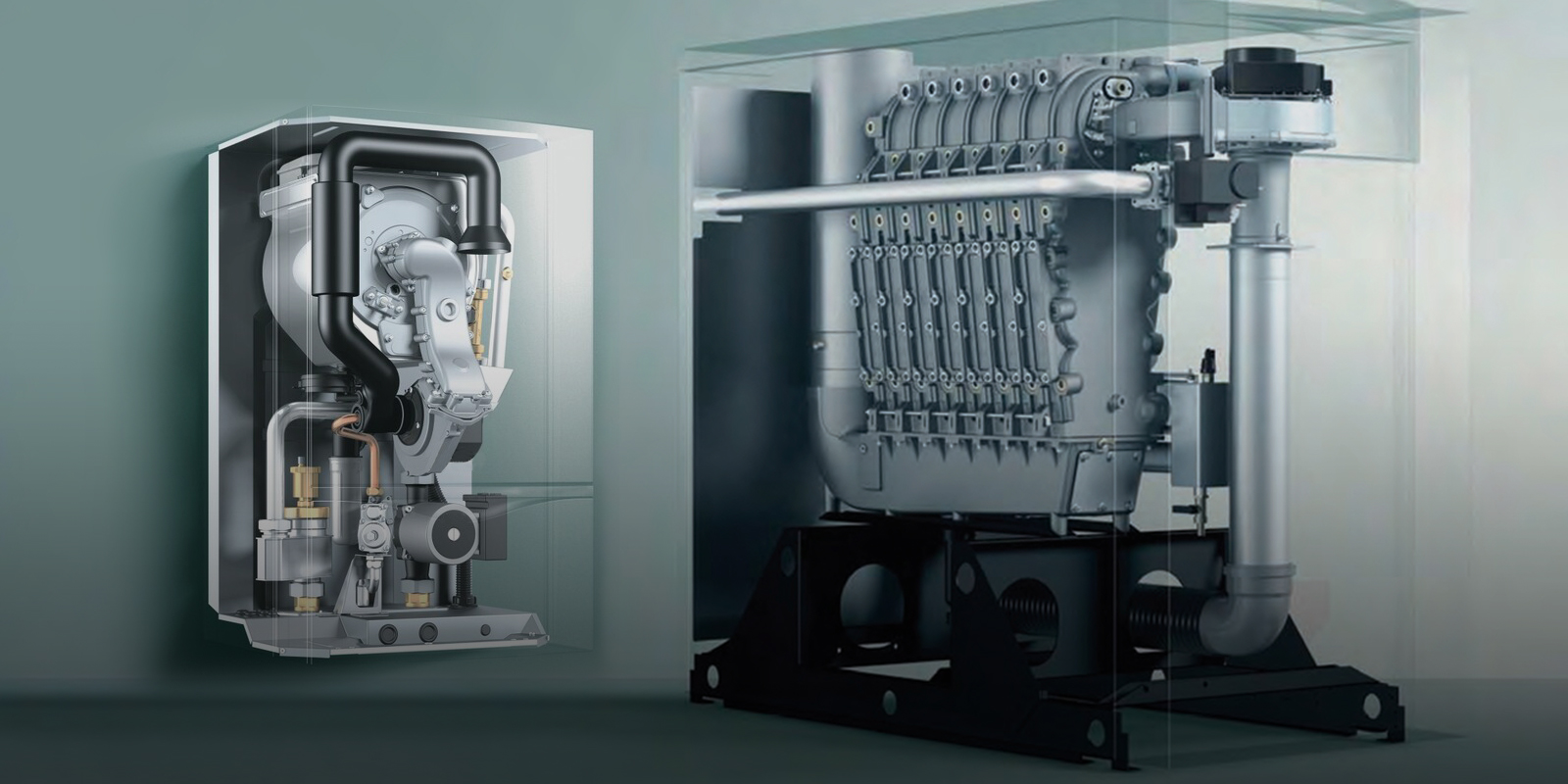

Intelligent Combustion Systems for Residential Wall-Hung Boilers: Elevating Traditional Heating Standards

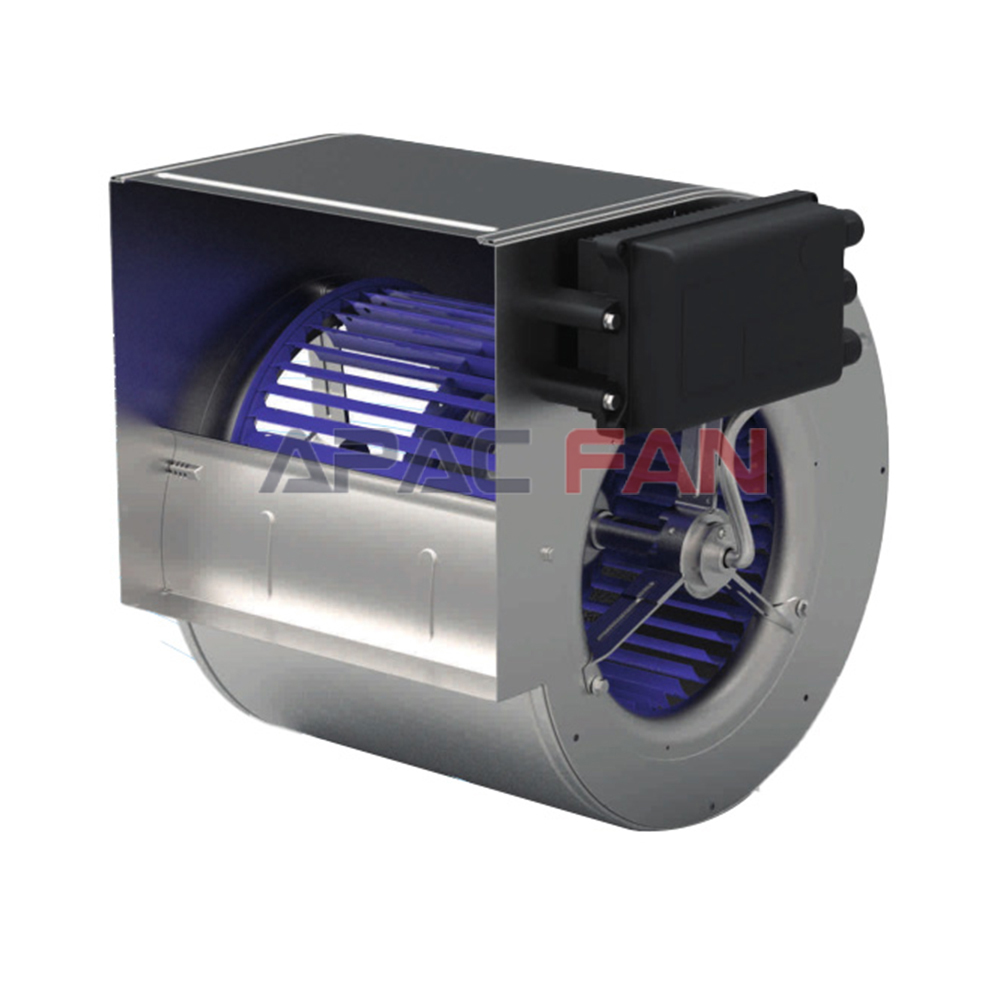

In the residential wall-hung boiler segment, ebm-papst has launched a high-efficiency, user-friendly intelligent combustion system. By precisely controlling the air-gas mixture ratio, the system breaks through the efficiency limitations of traditional boilers, injecting new momentum into the sustainable development of the heating industry. Compatible with both pneumatic and electronic control systems, the solution adapts to mainstream wall-hung boiler models on the market, enabling upgrades without large-scale equipment modifications and reducing client application costs.

The system’s core strength lies in "precision mixing + wide-range modulation." Through the scientific integration of dedicated fans with various Venturi tubes and valve groups, it achieves the optimal air-gas mixture ratio. Venturi tubes automatically adjust air intake based on gas flow, while the fan’s stable air supply ensures complete gas combustion, minimizing emissions of harmful substances such as carbon monoxide and nitrogen oxides. Valve groups utilize high-precision control technology to real-time regulate gas supply, forming a linked control system with the fan that achieves a maximum modulation ratio of 1:15. This allows the boiler to flexibly switch between low and high loads based on indoor temperature demands—reducing output power at night to maintain temperature while cutting gas consumption, and rapidly increasing power during daytime to meet heating needs, eliminating energy waste.

Moreover, the intelligent combustion system offers convenient operation. For pneumatic control systems, it adopts a mechanical linkage structure that enables automatic adjustment without external power supply, making it suitable for areas with unstable electricity, such as rural regions. For electronic control systems, it is equipped with an intelligent chip that allows real-time monitoring of combustion status and energy consumption data via a mobile app or boiler control panel. Users can track daily gas usage and set personalized heating modes—such as "away mode" or "sleep mode"—balancing comfort and energy efficiency.

From traditional wall-hung boilers to modern heat pump systems, ebm-papst remains committed to technological innovation. Through the continuous optimization of its two core heating solutions, the company not only helps clients "break the circle" of heating scenarios but also drives the entire heating industry toward greater efficiency, low carbon emissions, and intelligence. Looking ahead, ebm-papst will continue to deepen its presence in the broad heating sector, focusing on client pain points and developing more scenario-adaptable heating technologies to contribute to the construction of a sustainable heating ecosystem.

English

English Français

Français Deutsch

Deutsch Português

Português Español

Español русский

русский  한국어

한국어 العربية

العربية Italiano

Italiano Indonesia

Indonesia Schweiz

Schweiz Polski

Polski Nederlands

Nederlands ישראל - עברית

ישראל - עברית Perzisch

Perzisch ไทย

ไทย 日本語

日本語 ኢትዮ-አማርኛ

ኢትዮ-አማርኛ Việt Nam

Việt Nam Kiswahili

Kiswahili Srpski

Srpski Ελληνικά

Ελληνικά 繁體中文

繁體中文